Training Course on Supply Chain Resilience and Disruption Management

Training Course on Supply Chain Resilience & Disruption Management is meticulously designed to equip professionals with the advanced strategies, cutting-edge tools, and actionable frameworks necessary to anticipate, mitigate, and rapidly recover from these unforeseen challenges, transforming vulnerabilities into competitive advantages.

Skills Covered

Course Overview

Training Course on Supply Chain Resilience & Disruption Management

Introduction

The contemporary global landscape is characterized by unprecedented volatility, uncertainty, complexity, and ambiguity (VUCA). Supply chain disruptions, from geopolitical conflicts and natural disasters to cyberattacks and pandemics, are no longer anomalies but frequent occurrences, profoundly impacting business continuity and profitability. Training Course on Supply Chain Resilience & Disruption Management is meticulously designed to equip professionals with the advanced strategies, cutting-edge tools, and actionable frameworks necessary to anticipate, mitigate, and rapidly recover from these unforeseen challenges, transforming vulnerabilities into competitive advantages.

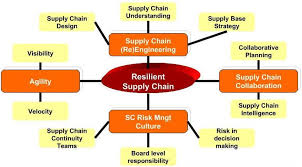

Our program focuses on building adaptive supply chain networks that can not only withstand shocks but also emerge stronger and more efficient. Through a blend of theoretical knowledge and practical application, participants will delve into risk assessment methodologies, develop robust contingency plans, and explore innovative digital transformation solutions. This training is essential for organizations seeking to enhance their operational excellence, safeguard their brand reputation, and ensure sustainable growth in an increasingly unpredictable world.

Course Duration

10 days

Course Objectives

Upon completion of this comprehensive training, participants will be able to:

- Understand the evolving landscape of global supply chain risks and their potential impact on organizational performance.

- Master advanced supply chain risk assessment and vulnerability analysis techniques.

- Develop and implement proactive risk mitigation strategies across the entire supply chain lifecycle.

- Design and build inherently resilient supply chain networks with enhanced flexibility and agility.

- Formulate effective disruption management protocols and crisis response plans.

- Leverage digital technologies such as AI, Machine Learning, and Blockchain for improved supply chain visibility and predictive analytics.

- Optimize inventory management strategies for resilience, moving beyond traditional Just-In-Time (JIT) to Just-In-Case (JIC) where appropriate.

- Strengthen supplier relationships and implement robust supplier diversification and redundancy programs.

- Conduct comprehensive scenario planning and stress testing to validate supply chain robustness.

- Implement effective business continuity planning (BCP) tailored for supply chain operations.

- Develop a culture of proactive risk management and continuous improvement within their organizations.

- Measure and report on supply chain resilience metrics and Key Performance Indicators (KPIs).

- Navigate regulatory compliance and geopolitical risks in a complex global trade environment.

Organizational Benefits

- Ensuring uninterrupted operations amidst disruptions, minimizing downtime and production losses.

- Mitigating the economic impact of supply chain failures, avoiding costly expedited shipping and lost sales.

- Enabling faster adaptation to market changes, demand fluctuations, and unforeseen events.

- Building confidence with customers, suppliers, and investors through demonstrated preparedness.

- More efficient use of inventory, capital, and human resources through predictive insights.

- Differentiating the organization by consistently delivering products/services even during challenging times.

- Projecting an image of reliability, stability, and proactive management.

- Laying a robust foundation for long-term viability and expansion in a volatile global economy.

- Empowering leaders with actionable insights from real-time supply chain data.

- Embedding a proactive, risk-aware mindset throughout the organization.

Target Audience

- Supply Chain Managers and Directors

- Procurement Officers and Managers

- Logistics and Distribution Managers

- Operations Managers

- Risk Management Professionals

- Business Continuity Planners

- Strategic Planning Managers

- Consultants specializing in Supply Chain Solutions

Course Outline

Module 1: Introduction to Supply Chain Resilience & Disruption Management

- Defining Supply Chain Resilience, Agility, and Robustness.

- Understanding the VUCA world and its impact on global supply chains.

- Historical context: Major supply chain disruptions (e.g., COVID-19, Suez Canal blockage, geopolitical conflicts).

- The business imperative for resilient supply chains.

- Case Study: The impact of the Fukushima earthquake and tsunami on the automotive industry supply chain.

Module 2: Supply Chain Risk Identification and Assessment

- Categorization of supply chain risks

- Tools and techniques for comprehensive risk identification

- Risk mapping and heat map development for visualization.

- Quantitative and qualitative risk assessment methodologies.

- Case Study: Assessing cybersecurity risks in a modern manufacturing supply chain.

Module 3: Developing a Resilient Supply Chain Strategy

- Strategic frameworks for building resilience (e.g., diversification, redundancy, regionalization/localization).

- Balancing efficiency and resilience: The "lean vs. resilient" paradox.

- Designing flexible supply chain networks.

- Integrating resilience into strategic planning and decision-making.

- Case Study: How leading electronics manufacturers diversified their supply base post-COVID-19.

Module 4: Supply Chain Visibility & Transparency

- Importance of end-to-end supply chain visibility.

- Leveraging real-time data for proactive decision-making.

- Technologies enabling visibility: IoT, RFID, GPS tracking.

- Challenges in achieving true supply chain transparency.

- Case Study: A global apparel brand implementing real-time tracking for ethical sourcing and disruption response.

Module 5: Digital Transformation for Supply Chain Resilience

- The role of AI and Machine Learning in predictive analytics and demand forecasting.

- Blockchain for enhanced traceability and trust across the supply chain.

- Automation and robotics in warehousing and logistics for increased resilience.

- Digital twins for scenario simulation and optimization.

- Case Study: A logistics company using AI for dynamic route optimization during severe weather.

Module 6: Supplier Risk Management and Collaboration

- Strategies for comprehensive supplier risk assessment and onboarding.

- Developing strong, collaborative relationships with critical suppliers.

- Implementing multi-sourcing, dual-sourcing, and strategic alliances.

- Contractual clauses and service level agreements (SLAs) for resilience.

- Case Study: A pharmaceutical company building robust partnerships with API suppliers in diverse geographies.

Module 7: Inventory Optimization for Disruption

- Moving from Just-In-Time (JIT) to Just-In-Case (JIC) for critical components.

- Determining optimal safety stock levels and buffer inventories.

- Strategic stockpiling and inventory positioning.

- Dynamic inventory management systems.

- Case Study: An automotive OEM adjusting inventory strategies to mitigate semiconductor shortages.

Module 8: Scenario Planning & Stress Testing

- Techniques for developing plausible supply chain disruption scenarios.

- Conducting stress tests and simulations to evaluate resilience.

- Identifying vulnerabilities through "what-if" analyses.

- Developing playbooks for different disruption scenarios.

- Case Study: A food and beverage company simulating a major transport network disruption.

Module 9: Crisis Management & Emergency Response

- Establishing a dedicated supply chain crisis management team.

- Developing clear communication protocols during disruptions (internal and external).

- Rapid assessment of disruption impact and prioritization of response actions.

- Emergency logistics and alternative routing strategies.

- Case Study: A retail giant's swift response to port congestions and shipping delays during peak season.

Module 10: Business Continuity Planning (BCP) for Supply Chains

- Integrating supply chain resilience into the broader organizational BCP.

- Developing recovery time objectives (RTO) and recovery point objectives (RPO) for supply chain processes.

- Creating detailed continuity plans for critical functions.

- Regular testing and updating of BCPs.

- Case Study: A tech company's comprehensive BCP for its global manufacturing operations.

Module 11: Geopolitical and Regulatory Risks

- Understanding the impact of trade wars, tariffs, and political instability.

- Navigating complex international regulations and compliance requirements.

- Strategies for building resilience against geopolitical shocks.

- Ethical sourcing and sustainability in a disrupted environment.

- Case Study: A multinational firm adapting its supply chain to comply with new international trade agreements.

Module 12: Supply Chain Security & Cyber Resilience

- Protecting against theft, counterfeiting, and cargo crime.

- Cybersecurity threats to supply chain systems and data.

- Implementing robust IT security measures and incident response plans.

- Physical security of logistics and warehousing facilities.

- Case Study: A logistics provider recovering from a major ransomware attack on its operational systems.

Module 13: Performance Measurement & Continuous Improvement

- Key Performance Indicators (KPIs) for measuring supply chain resilience.

- Establishing a framework for continuous monitoring and evaluation.

- Post-disruption analysis and lessons learned.

- Implementing corrective and preventive actions (CAPA).

- Case Study: A manufacturing company's journey of continuous improvement in supply chain resilience following a major product recall.

Module 14: Human Factor in Supply Chain Resilience

- Building a resilient organizational culture.

- Training and empowering supply chain personnel for disruption response.

- Cross-functional collaboration and communication.

- Leadership in times of crisis.

- Case Study: A major retailer's internal communication strategy during widespread store closures due to a pandemic.

Module 15: Future Trends in Supply Chain Resilience

- Emerging technologies and their potential impact (e.g., Quantum Computing, Web3).

- Circular economy principles and their role in resilience.

- Increased focus on localized and regional supply chains.

- The evolving role of the Chief Supply Chain Officer.

- Case Study: A startup leveraging additive manufacturing (3D printing) for on-demand production and localized supply.

Training Methodology

This training course employs a highly interactive and practical methodology to ensure maximum participant engagement and knowledge retention. The approaches include:

- Expert-Led Presentations: Engaging lectures by industry veterans and subject matter experts.

- Interactive Discussions: Fostering knowledge sharing and peer learning through group discussions.

- Case Studies: In-depth analysis of real-world supply chain disruptions and successful resilience strategies.

- Practical Exercises & Workshops: Hands-on activities to apply learned concepts and develop actionable plans.

- Scenario-Based Simulations: Realistic simulations of supply chain disruptions to test decision-making under pressure.

- Group Projects: Collaborative problem-solving exercises to develop comprehensive resilience strategies.

- Q&A Sessions: Opportunities for participants to address specific challenges and gain expert insights.

- Video Resources: Illustrative videos showcasing best practices and industry trends.

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e.