Training Course on Wireline Operations and Techniques

Training Course on Wireline Operations and Techniques delves into the fundamental principles of wireline operations, the types of wireline used (slickline, braided line, and electric line), and the diverse applications in well completion, servicing, workover, and production.

Course Overview

Training Course on Wireline Operations and Techniques

Introduction

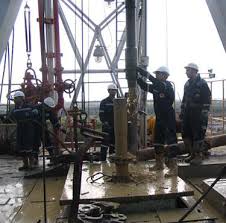

Wireline operations are essential in the oil and gas industry, particularly during well completion and production phases. These operations involve deploying specialized tools and equipment into the wellbore using a strong, slender wire cable. Wireline techniques enable a wide array of critical tasks, including downhole surveys, logging, perforating, well intervention, and the manipulation of subsurface equipment. A comprehensive understanding of wireline equipment, pressure control, and various intervention techniques is crucial for safe and efficient operations. This training course provides a detailed overview of wireline operations, covering equipment, techniques, safety procedures, and best practices for optimizing well performance and ensuring well integrity.

This course delves into the fundamental principles of wireline operations, the types of wireline used (slickline, braided line, and electric line), and the diverse applications in well completion, servicing, workover, and production. Emphasis will be placed on rigless well intervention, highlighting the cost savings and efficiency gains compared to traditional rig-based operations. Participants will gain practical knowledge of downhole tools, surface equipment, and operational contingencies, equipping them with the skills to plan and execute wireline jobs effectively while adhering to stringent safety standards and regulatory requirements.

Course Duration

5 days

Course Objectives

Upon completion of this training course, participants will be able to:

- Identify wireline types (slickline, braided line, electric line) and their specific applications in well operations.

- Explain the function of slickline equipment and its role in various downhole interventions.

- Describe the applications of braided line in more complex and demanding wellbore tasks.

- Outline the features and uses of electric line for logging, perforating, and production logging.

- Recognize and explain pressure control equipment used in wireline operations to maintain well integrity.

- Describe various downhole tools and their functions in well completion, servicing, and intervention.

- Understand the principles of running and pulling tools, including the use of locks, standing valves, and landing nipples.

- Explain flow control equipment and its manipulation using wireline techniques.

- Identify and describe wireline fishing operations for retrieving lost or stuck tools and equipment.

- Assess the risks associated with wireline operations and implement appropriate mitigation measures.

- Apply best practices for rigless intervention safety and operational efficiency.

- Evaluate different well intervention methods and select the most suitable approach for specific scenarios.

- Apply up-to-date knowledge of wireline techniques in well completion, servicing, workover, and production enhancement.

Organizational Benefits

Implementing this Wireline Operations and Techniques training course will provide several key benefits to organizations:

- Trained personnel will be proficient in planning and executing wireline operations, leading to reduced downtime and optimized well performance.

- Comprehensive training on pressure control, equipment handling, and risk mitigation will minimize incidents and ensure a safer working environment.

- Efficient rigless interventions and reduced operational errors will contribute to significant cost savings.

- Skilled operators can effectively deploy wireline techniques to optimize production and enhance hydrocarbon recovery.

- Understanding pressure control and downhole conditions through wireline operations helps in maintaining long-term well integrity.

- The course content will align with industry best practices and regulatory requirements, ensuring compliance.

- Investing in this training will develop a competent and knowledgeable workforce capable of handling complex wireline operations.

- Proper handling and operation of wireline equipment by trained personnel will minimize damage and extend equipment lifespan.

Target Audience

This training course is designed for professionals involved in well operations and interventions in the oil and gas industry, including:

- Wireline Operation Engineers

- Wireline Engineers

- Subsurface Engineers

- Production Engineers

- Field Support Personnel

- Petroleum Engineers

- Production Technologists

- Well Intervention Specialists

Course Outline

Module 1: Introduction to Wireline Operations

- Overview of wireline history and development in the oil and gas industry.

- Importance of wireline operations in well completion and production.

- Types of wireline: slickline, braided line, and electric line – characteristics and applications.

- Basic principles of downhole intervention and data acquisition using wireline.

- Safety regulations and best practices in wireline operations.

Module 2: Slickline Operations and Techniques

- Slickline equipment: wireline unit, power pack, and surface control.

- Pressure control equipment for slickline: stuffing box, lubricator, and blowout preventers (BOPs).

- Slickline tools and bottom hole assemblies (BHAs) for various applications.

- Running and pulling tools, gauge rings, and mechanical plugs using slickline.

- Basic slickline intervention techniques: scale removal, paraffin control, and flow control adjustments.

Module 3: Braided Line Operations and Techniques

- Braided line characteristics, strength, and applications compared to slickline.

- Braided line equipment and handling procedures.

- Pressure control equipment specific to braided line operations.

- Braided line tools for setting and retrieving subsurface safety valves (SSSVs).

- Applications in well integrity testing and remedial operations.

Module 4: Electric Line Logging and Perforating

- Principles of electric line logging and its importance in formation evaluation.

- Types of electric logs: gamma ray, resistivity, sonic, and density logs.

- Electric line equipment: logging tools, cables, and data acquisition systems.

- Perforating operations using electric line: charges, guns, and safety procedures.

- Production logging tools (PLTs) and their applications in monitoring well performance.

Module 5: Downhole Tools and Equipment

- Detailed overview of various downhole tools used in wireline operations.

- Flow control devices: nipples, locks, and sliding sleeve doors (SSDs).

- Setting and retrieving tools for packers and plugs.

- Gas lift valve installation and retrieval using wireline.

- Chemical injection mandrels and their deployment techniques.

Module 6: Pressure Control and Well Integrity

- Importance of pressure control during all wireline operations.

- Detailed explanation of surface pressure control equipment and its functions.

- Well barriers and barrier testing procedures.

- Risk assessment and management in pressure control operations.

- Emergency response procedures in case of pressure control failure.

Module 7: Wireline Fishing Operations

- Common causes of stuck tools and wireline breaks.

- Fishing tools and techniques for retrieving lost equipment.

- Wireline spears, grabs, and overshots – principles of operation.

- Fishing procedures for different scenarios: wire broken at surface, downhole, or tool string separation.

- Best practices for preventing fishing incidents and ensuring successful retrieval.

Module 8: Operational Planning and Best Practices

- Job planning and risk assessment for wireline operations.

- Contractor proposal evaluation and critical job design considerations.

- Industry best practices for safe and efficient wireline interventions.

- Lessons learned from case studies and operational challenges.

- Emerging technologies and advancements in wireline operations.

Training Methodology

This training course will employ a variety of interactive and practical methods to ensure effective learning, including:

- Lectures and Presentations: Covering the theoretical aspects of wireline operations and techniques.

- Interactive Discussions: Encouraging participants to share experiences and engage in problem-solving.

- Case Studies: Analyzing real-world scenarios and operational challenges in wireline.

- Video Demonstrations: Illustrating the operation of equipment and various wireline techniques.

- Group Exercises: Facilitating collaborative learning and application of concepts.

- Practical Simulations (if facilities allow): Providing hands-on experience with wireline equipment and tools.

- Question and Answer Sessions: Addressing participant queries and reinforcing understanding.

Register as a group from 3 participants for a Discount

Send us an email: info@datastatresearch.org or call +254724527104

Certification

Upon successful completion of this training, participants will be issued with a globally- recognized certificate.

Tailor-Made Course

We also offer tailor-made courses based on your needs.

Key Notes

a. The participant must be conversant with English.

b. Upon completion of training the participant will be issued with an Authorized Training Certificate

c. Course duration is flexible and the contents can be modified to fit any number of days.

d. The course fee includes facilitation training materials, 2 coffee breaks, buffet lunch and A Certificate upon successful completion of Training.

e. One-year post-training support Consultation and Coaching provided after the course.

f. Payment should be done at least a week before commence of the training, to DATASTAT CONSULTANCY LTD account, as indicated in the invoice so as to enable us prepare better for you.